Carbon Fiber Molded

Carbon fiber is a kind of polymer, which is made of thin, strong crystalline filaments of carbon that is used to strengthen material.

It is said that carbon fiber can be thinner than a strand of human hair and gets its strength when twisted together like yarn. The most well-known properties of carbon fiber is the great strength and also light weight, normally, strength of carbon fiber is five times as steel and twice stiff than steel. Besides, carbon fiber is also widely used because of its high tensile strength, high chemically resistant

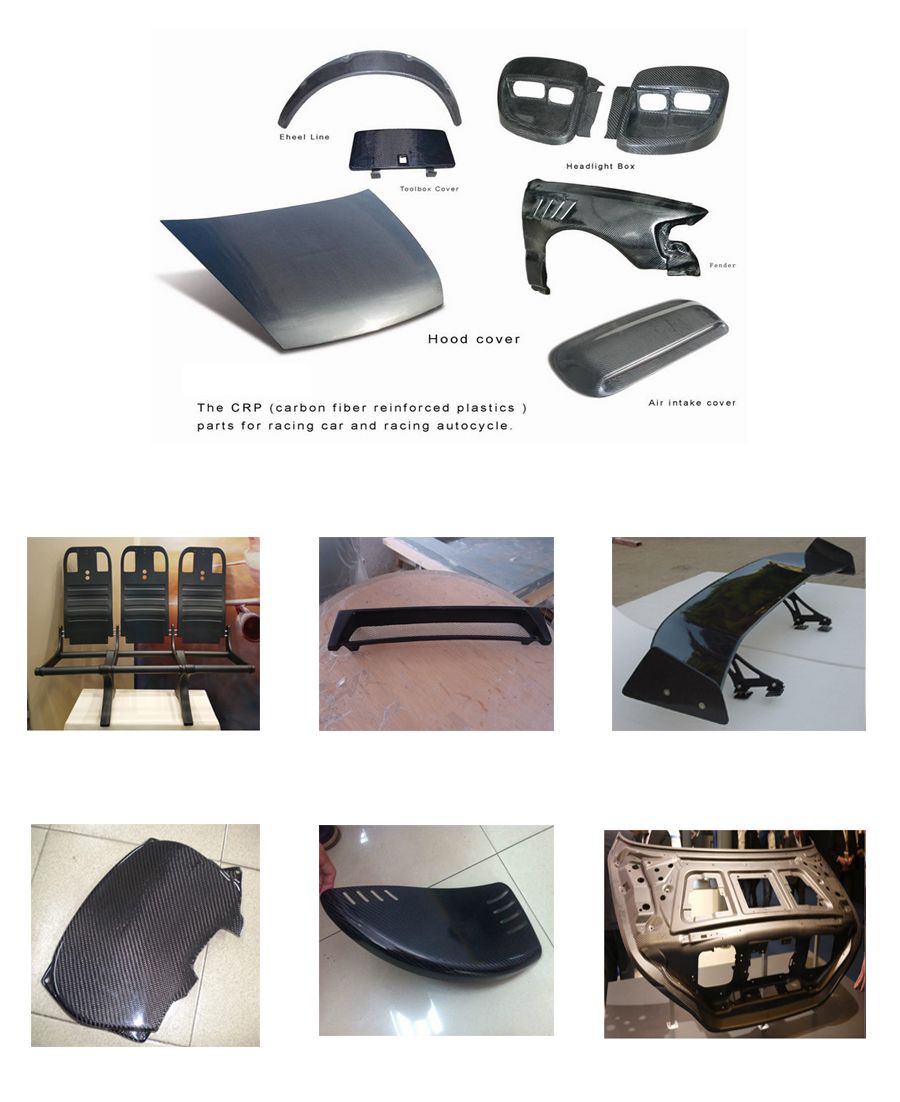

and also high temperature tolerance with low thermal expansion. Finally, parts made from carbon fiber are always with a unique luxurious appearance. With all those advantage than normal steel or plastic, now carbon fiber is at a leading position in the market for manufacturing composite materials, which is widely used in different fields, especially the aircraft wings, military, racing car bodies, bike frames, golf club shafts, fishing rods, sailboat masts and also automobile like the drive shafts etc.

Currently there are three processes that are used toproduce carbon fiber products: High temperature moulding, Vacuum Hot Pressing Tank Forming and Winding forming.

High temperature moulding: Carbon fibre prepreg is placed between upper and lower moulds. After closing the moulds, the moulds are placed on the hydraulic moulding table. After curing the resin at high temperature and high pressure for a certain time, the blanks of carbon fibre products can be obtained. Temperature control is the most important step in the forming process. In general, the higher the temperature of

the die and the better the material fluidity in a certain temperature range, the faster the curing speed will increase and the production efficiency will be improved. But if the temperature is too high, the cross-linking reaction of the material will start prematurely. Initially, the solidification inside and outside the material is not uniform, and it is easy to crack and deform. The main advantage of this process is the high content of carbon fibers in carbon fibre composites, which can make the performance more excellent.

Vacuum Hot Pressing Tank Forming: Like some products with box and shell shape, some products with complex structure and larger specifications are suitable for this process. The general process is: the carbon fiber preprepreg is pasted on the surface of the die, the whole is packed in a vacuum bag, pumped into a vacuum state, then placed in a hot-pressing tank, and vacuum pumped. After a period of vacuum heating, the resin was cured and the product blank was obtained. The main defect of carbon fibre products made by hot-pressing tank process is layered. We can reduce the residual stress through Galen design and process.